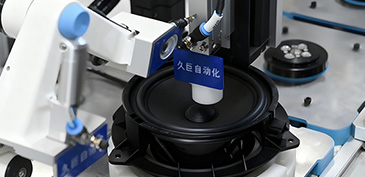

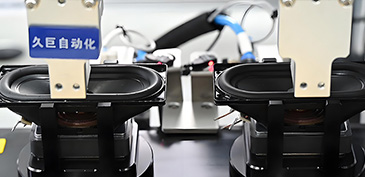

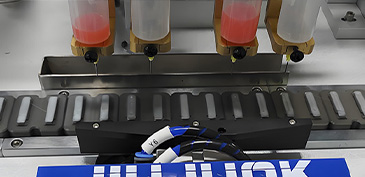

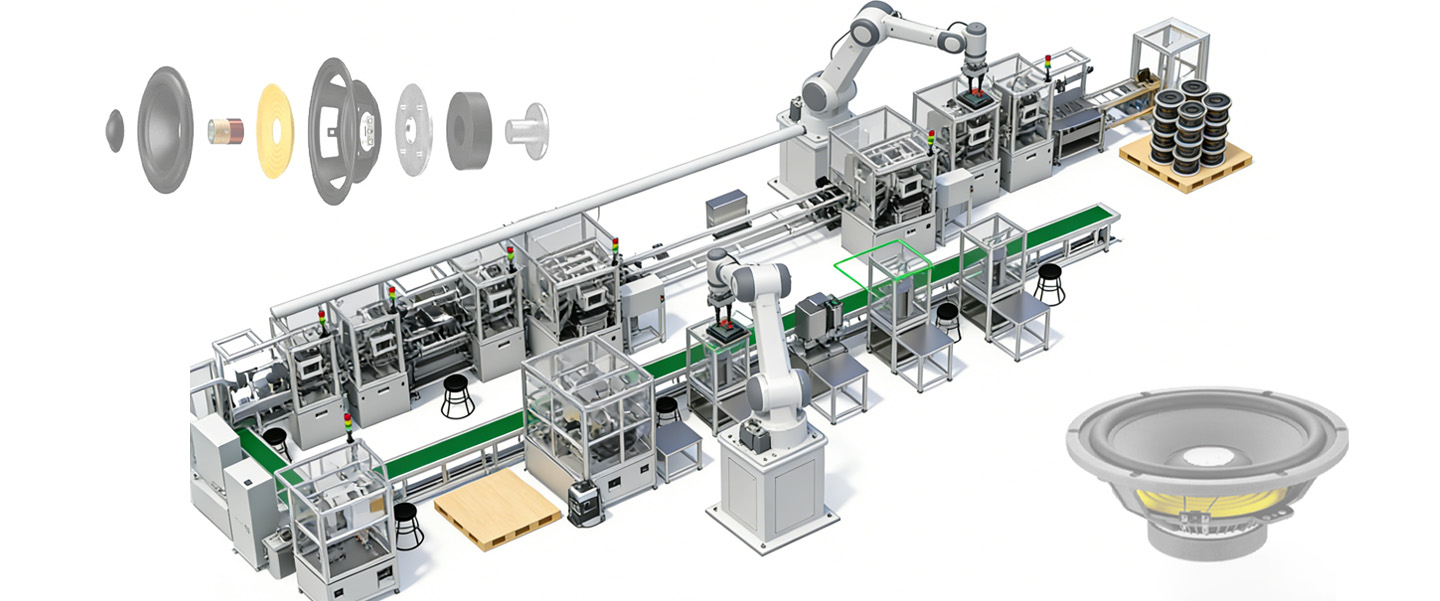

The production line is designed to meet the needs of micro-component assembly and accurately covers the core production process. In view of the thin structure of the cell phone speaker unit and the precision welding requirements of the internal welding Bluetooth headset core, the production line adopts the structure of "segmented precision assembly + core process enhancement" to complete the whole process of magnetic circuit assembly, voice coil winding, diaphragm lamination, lead welding, performance testing and other operations in sequence. Magnetic circuit assembly is equipped with customized miniature vibration plate feeding, with high-definition CCD visual positioning system, to achieve T-iron, miniature magnets and other small-sized parts of the accurate grabbing and positioning, positioning accuracy of ± 0.01mm, to completely solve the problem of manual operation of the miniature parts are prone to drift. The internal welding process is exclusively equipped with a micro laser welding module, with a welding precision of 0.02mm, effectively avoiding the problems of false welding and leakage that are easily caused by manual welding, and guaranteeing the stability of the electrical connection of the earphone core.

High-standard hardware configuration is the core guarantee of precision and stability. The production line fully adopts the core parts of the first-tier brands at home and abroad, and the drive system adopts Panasonic servo motors from Japan to ensure the precise and controllable operation of each station; the detection unit is equipped with Keens vision sensors from Germany to realize the precise identification of tiny defects; the transmission structure adopts Swiss precision ball screws, and with the customized precision fixtures, the mechanical error during the assembly process can be controlled to be less than 0.005mm. For the assembly characteristics of micro components, the jigs are made of aviation-grade aluminum alloy through five-axis machining centers, and the surface is anodized to ensure rigidity and wear-resistant characteristics, and the service life of a single set of jigs can reach more than 100,000 hours, which provides a solid support for the consistency of the products.

Intelligent control and flexible production design enhance core competitiveness. The operation level is equipped with Chinese visual human-machine interaction system, with 10-inch touch screen, real-time display of the operating status of each station, production capacity data and fault warning, support for one-key storage and invocation of process parameters, and can be independently operated by new employees after 2 hours of training. For the production of different types of cell phone speakers and Bluetooth headset cores, the production line supports modular quick changeover, through the replacement of special fixtures and call the preset parameters, the changeover time can be controlled within 15-20 minutes, to adapt to the production of 10mm miniature cell phone speakers to 15mm Bluetooth headset cores of multi-specification needs. In terms of production efficiency, the hourly production capacity can reach 1800-2200 sets, 8-10 times higher than the traditional manual production line, a single production line can reduce 90% labor input, significantly reducing labor costs and management costs.

The quality control system guarantees high-end demand in all aspects. The production line sets up multiple inspection nodes in key stations such as magnetic circuit assembly, diaphragm lamination, welding, etc. Through multi-dimensional inspections such as visual inspection, pressure sensing, acoustic testing, etc., real-time screening of dimensional deviation, misalignment of assembly, abnormal sound quality and other defective products, with an accuracy of 99.8%. The whole machine adopts a fully enclosed dust-proof and anti-static design, and is equipped with a constant-temperature and constant-humidity control system, which provides a clean and stable production environment for assembly of miniature parts, increasing the product qualification rate from 91% to more than 99.7%. Stable production environment for the assembly of micro-components, product qualification rate increased from 91% in manual assembly to more than 99.7%. Meanwhile, it is equipped with a production data traceability system, which realizes full traceability of the production process of each set of products, perfectly adapting to the quality control requirements of high-end headset brands, and becoming the core equipment for cell phone and bluetooth headset manufacturers to realize large-scale, high-quality production.

jiujuauto

jiujuauto