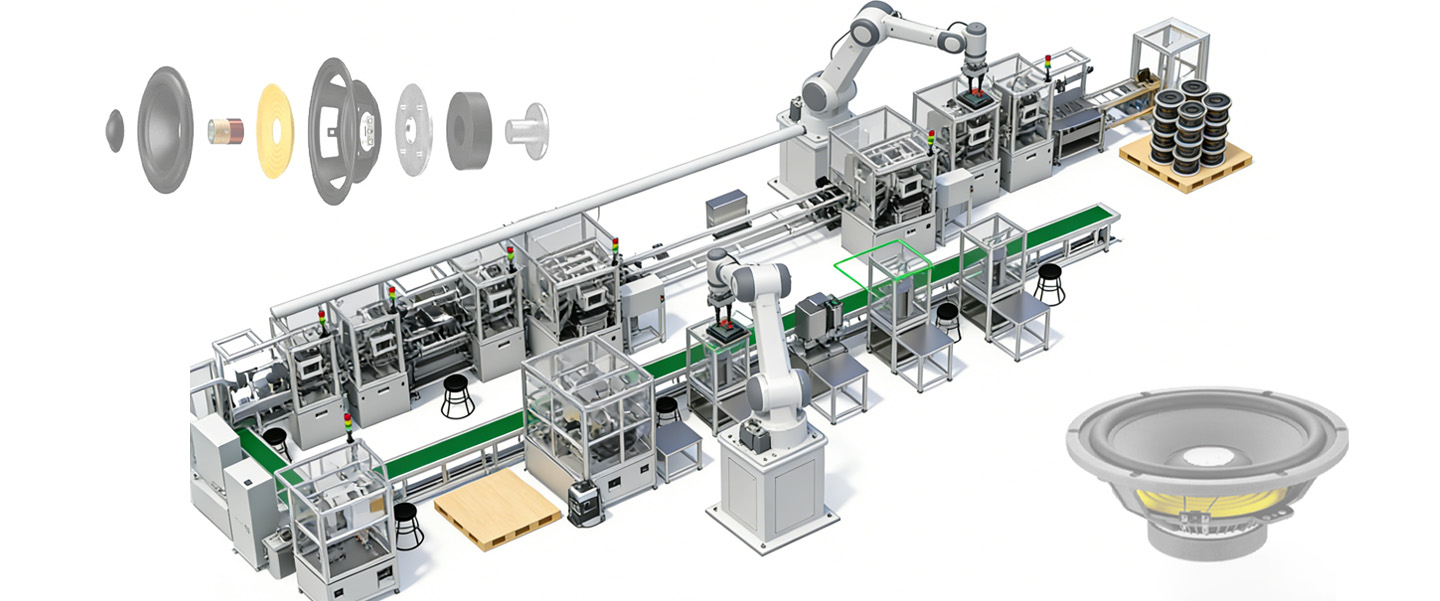

Speaker Automation Solutions

Speaker automation solution

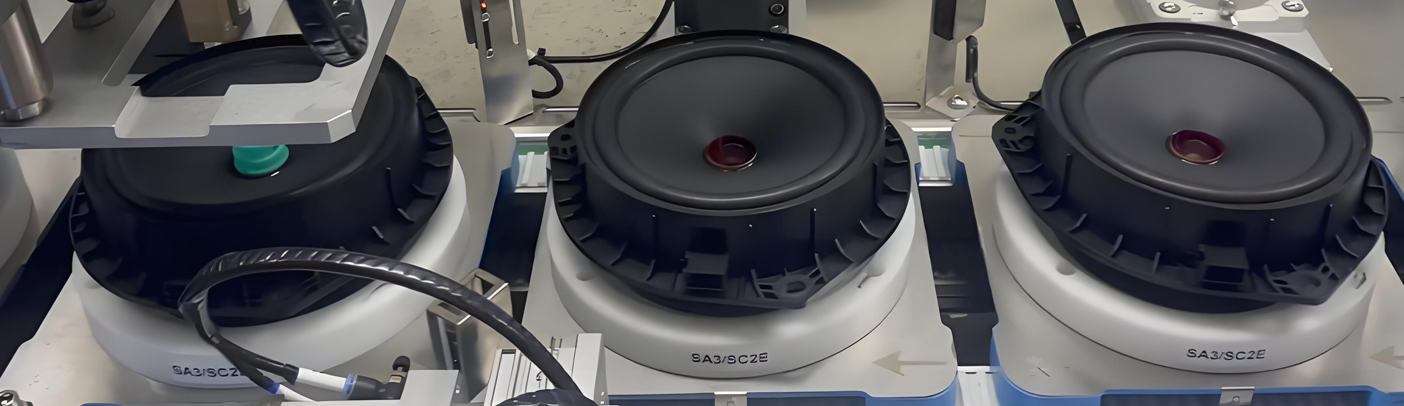

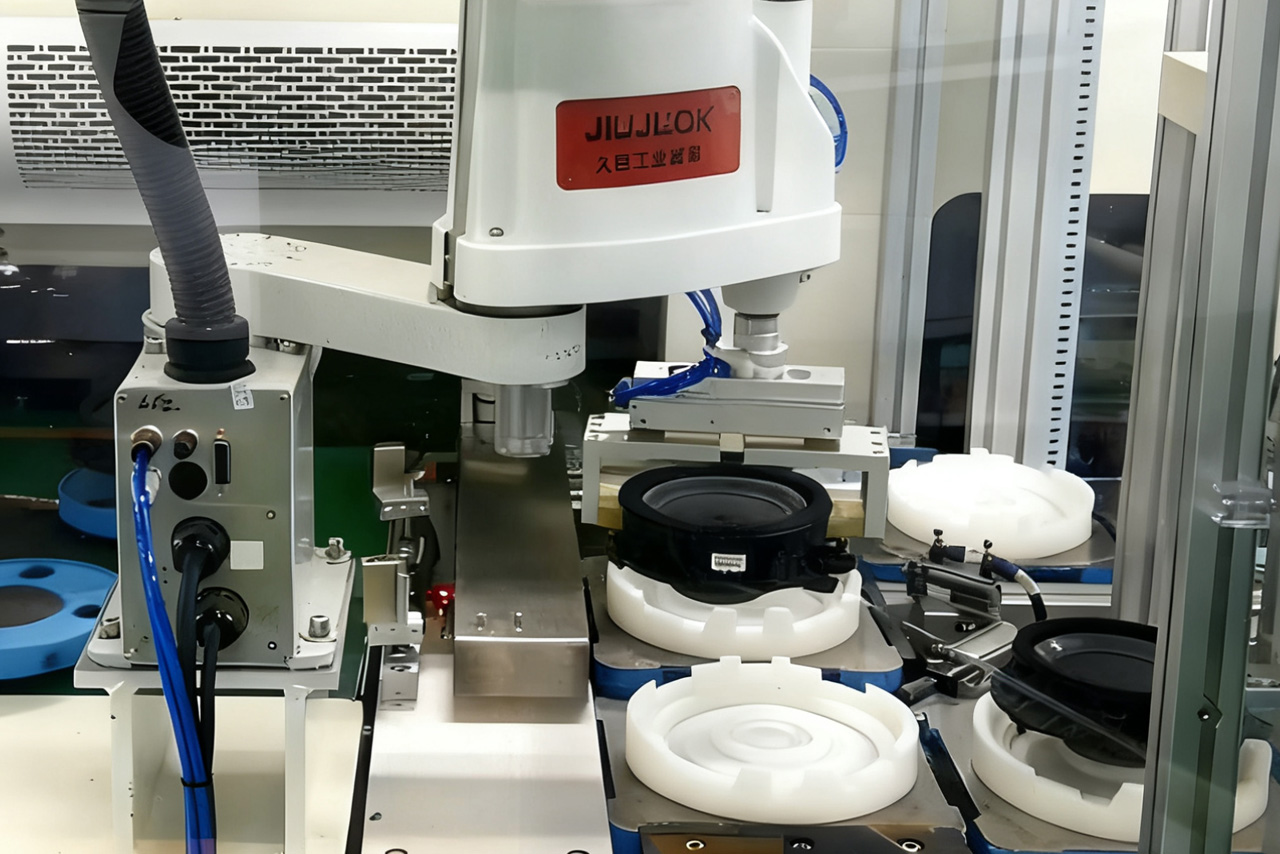

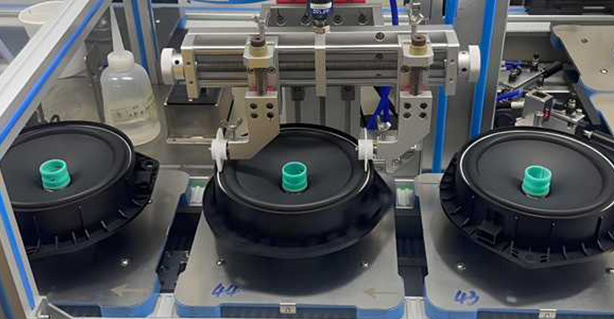

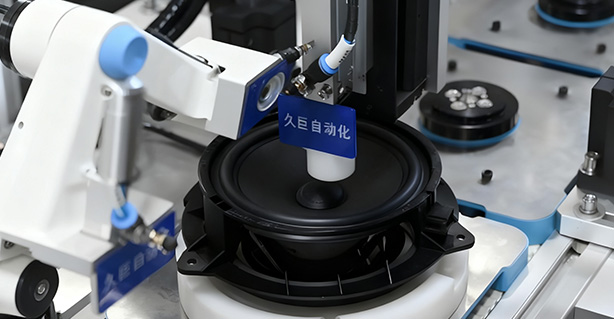

JiuJu Automation focuses on the intelligent upgrading of the whole process of speakers, integrating the four core technologies of visual inspection, precision assembly, AI quality inspection and data traceability to provide customized solutions for TWS headphones, car audio, multimedia smart audio speakers, etc., and achieve production capacity increase of 300%+, yield rate of 99.8%, and reduce the comprehensive cost of 60%, completely solving the pain points of the industry, such as manual dependence, stable quality control and delivery cycle. dependence, unstable quality control, long delivery cycle and other industry pain points. Based on the product characteristics and production scenarios of speakers, it creates a full-process automation system from the entry of raw materials to the release of finished products from the warehouse, covering the three major categories of micro, small and medium-sized, and adapting to the needs of multi-specification and multi-batch production.

jiujuauto

jiujuauto