Linear internal magnetic horn magnetic circuit machine double core how to solve the "multi-specification horn magnetic circuit production difficult" problem

A small factory specializing in the production of low-end consumer speakers encountered the core problem of "multi-size production" when expanding its market. With the diversification of speaker needs in the consumer electronics market, customers not only need the traditional ∅20mm regular-sized speakers, but also put forward ∅12mm mini-speakers, ∅35mm subwoofer, and other customized needs. However, the factory's original magnetic circuit production equipment only supports U shells and magnets within ∅25mm, and is unable to produce large-size magnetic circuit assemblies; if you want to produce small-size products, you need to manually adjust the parameters of the equipment, and each time you change the type of time-consuming nearly 3 hours, and the precision is difficult to ensure, resulting in the small-size magnetic circuit assemblies of the scrap rate of as high as 12%, the delivery of customized orders is often more than 15 days, and customer complaints rate is still high. The customer complaint rate remained high, and many potential collaborations fell through due to insufficient production capacity.

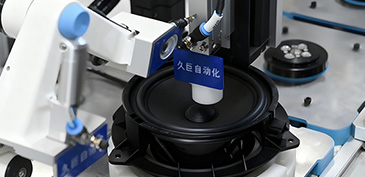

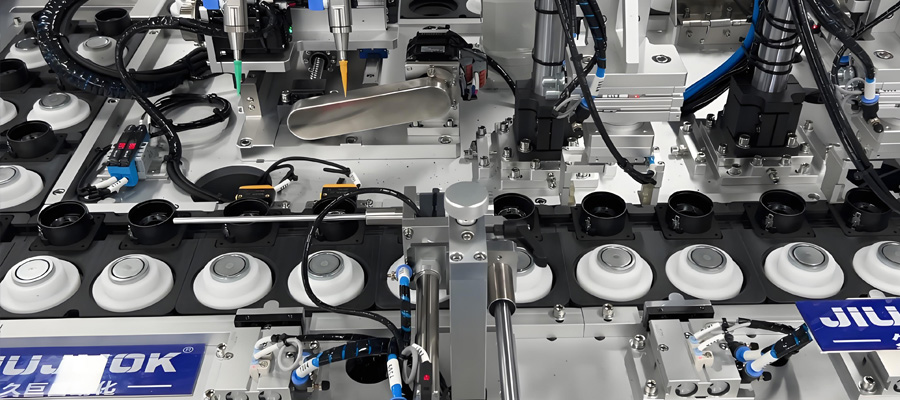

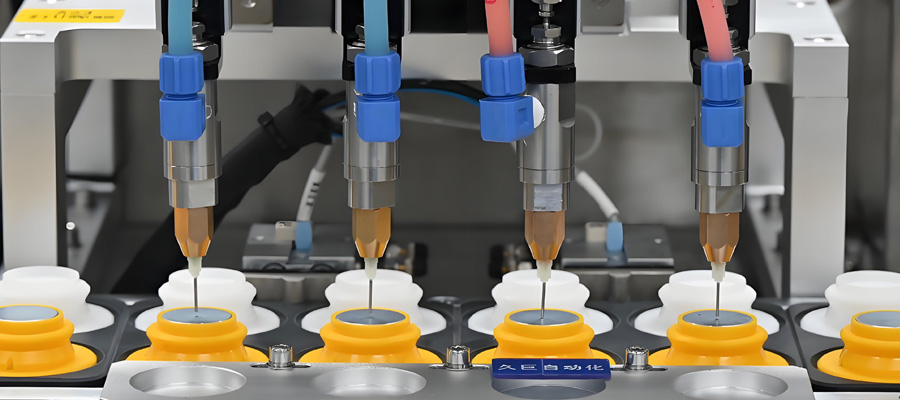

After learning about the characteristics of the linear internal magnetic circuit machine dual-core, the factory decisively invested in equipment upgrades. Starting from the actual needs of the horn magnetic circuit production, the size of this equipment fits the enterprise's pain points: the maximum specification of the U shell size ≤ ∅40mm, can cover the magnetic circuit of the ∅35mm subwoofer needs; magnet and washer size ∅9-∅30mm between, whether it is the ∅12mm mini-speaker of the small size of the magnets, or the ∅25mm regular speaker standard magnets, can be accurately adapted to. Adaptation. What's more, the size adjustment system of the equipment adopts digital control, when changing the shape, you only need to input the target size parameters in the operation panel, and the adjustment can be completed within 15 minutes without dismantling the molds manually, which greatly reduces the time and error of changing the shape.

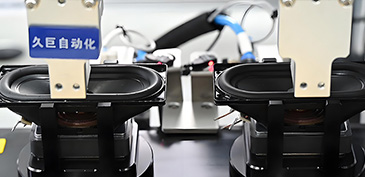

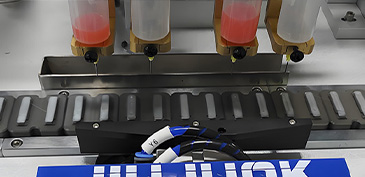

In addition to size adaptability, the production efficiency of the equipment has also brought surprises to the enterprise. The original equipment's magnetic circuit assembly capacity is only 900PCS/H, and the drying time is as long as 20 minutes, while the capacity of the linear internal magnetic circuit machine with two cores has been increased to 1200-1350PCS/H, and the drying time has been shortened to 8 minutes, and the capacity of a single day can still be stabilized at more than 8,000PCS even when switching the production of multi-specification, which is nearly doubled compared with the previous one. This means that enterprises do not need to worry about the delivery schedule of regular orders while undertaking customized orders, achieving a balance between "multiple specifications" and "high efficiency".

In order to further improve product quality, the plant also optimized the production process of the horn magnetic circuit by combining the equipment's internal magnetic magnetic circuit assembly solution. The internal magnetic magnetic circuit assembly program accurately fixes the relative positions of the U shell, magnet and washer through positioning pins, avoiding the problem of offset during manual assembly, so that the consistency of the magnetic performance of the magnetic circuit components is improved by 30%, and the stability of the speaker's sound quality is also improved. With the three-piece process, from raw material selection to finished product testing, each link has a clear standard, the operation of the production staff to enhance the standardization of the product pass rate from 88% to 98.5%.

Half a year after the equipment upgrade, the plant's market competitiveness has increased significantly: the proportion of customized orders increased from 15% to 40%, with 2 new smart wearable device customers; the delivery cycle of regular orders was shortened from 10 days to 5 days, and the repurchase rate of the customers increased from 60% to 85%; the cost of raw material loss was reduced by 12,000 yuan per month, and the net profit increased by 35% year-on-year. 35%. For small horn factory, linear internal magnetic circuit machine double core is not only a production equipment, but also a key help to promote the enterprise from "regular production" to "customization + high efficiency" transformation.

jiujuauto

jiujuauto